Rapid Prototyping Techniques, Benefits & Tools : How to Reduce Costs and Avoid Costly Design Mistakes?

Published: 06 September, 2025

Experience Design

Table of Contents

Rapid prototyping [Also known as “fast prototyping”] is a fast, cost-effective product development technique that transforms digital 3D designs into physical models using technologies like 3D printing, CNC machining, and molding. It enables teams to test concepts, gather real user feedback, and iterate quickly—significantly reducing time to market and development costs.

From startups testing Minimum Viable Product to global manufacturers refining final product designs, rapid prototyping empowers businesses to innovate with agility and precision. Whether you’re building an automotive component, a medical device, or a digital interface, the ability to “build to learn” and pivot fast can be a strategic advantage.

Let’s cover the full landscape of rapid prototyping—from tools and technologies to applications, benefits, and real-world examples. You’ll also discover how emerging trends like AI, XR, and sustainable prototyping are reshaping what’s possible in design and manufacturing.

If you’re exploring rapid prototyping for your next project, our product development consulting service helps you turn ideas into validated designs with the right tools and methods.

What Is Rapid Prototyping?

Rapid prototyping [Also known as “fast prototyping”] is a fast and iterative product development process that transforms digital CAD designs into physical models using additive (e.g., 3D printing), subtractive (e.g., CNC machining), or molding techniques. This approach allows teams to produce functional or conceptual prototypes quickly, enabling early testing, real-time feedback, and multiple design iterations—all before committing to full-scale manufacturing.

Whether used to refine product fit and function, validate usability, or simulate real-world conditions, rapid prototyping supports agile, user-centered design across hardware and software domains. Accelerating the concept-to-test cycle enables teams to minimize risks, improve collaboration, and deliver better-performing products faster and more affordably.

- Additive Manufacturing (e.g., FDM, SLA, SLS): Builds prototypes layer by layer, ideal for complex geometries and reduced material waste.

- Subtractive Manufacturing (e.g., CNC Machining): Cuts away material from solid blocks for precise, high-strength parts.

- Molding Techniques (e.g., silicone, urethane): Produce low-volume, high-fidelity prototypes without permanent tooling investment.

In addition to physical processes, rapid prototyping software enhances this workflow by enabling digital simulations, interactive wireframes, and virtual testing—reducing costs while improving design accuracy.

Rapid prototyping integrates seamlessly with digital tools such as CAD software, simulation platforms, and cloud-based design environments—making it highly scalable and adaptable for industries like automotive, medical devices, consumer electronics, fashion, and software.

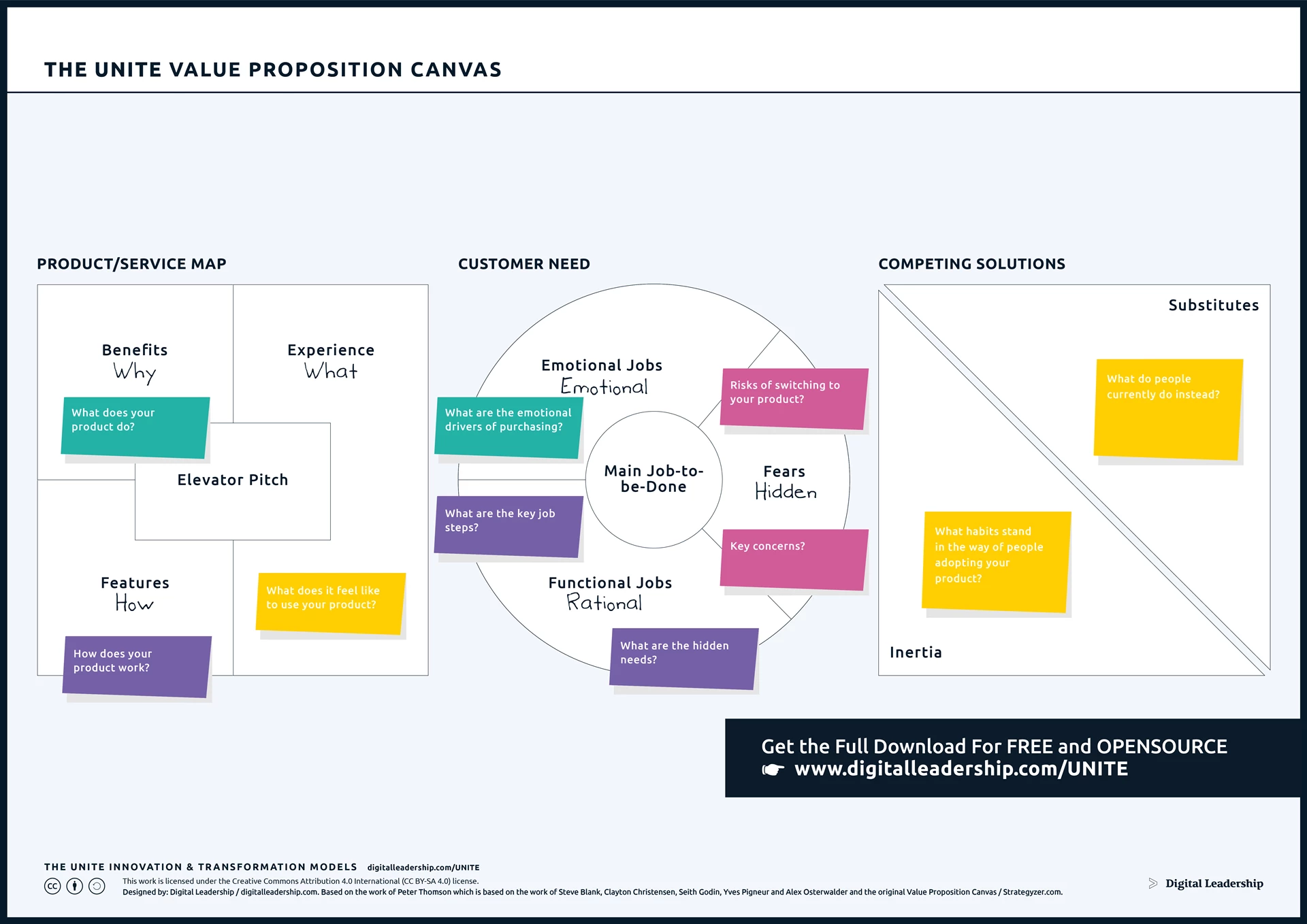

The UNITE Visualization Types and Customer Testing Approaches play a vital role in maximizing the impact of rapid prototyping by guiding teams in selecting the right prototype fidelity and testing method for each stage of development… Download it now.

Designed by: Digital Leadership AG

Rapid Prototyping vs. Traditional Prototyping

While both approaches aim to test and validate product designs, the methods, speed, and costs involved are drastically different. Traditional prototyping often requires high tooling costs and longer timelines, making it less viable for early-stage development or iterative changes. In contrast, rapid prototyping leverages digital tools and agile processes to deliver faster, more flexible, and cost-effective results.

Here’s how the two approaches compare:

|

Criteria |

Rapid Prototyping |

Traditional Prototyping |

|

Speed to Market |

Days to weeks |

Weeks to months |

|

Cost per Iteration |

Low (especially with digital methods like 3D printing) |

High (due to tooling, labor, and setup costs) |

|

Flexibility & Design Changes |

Very high—easy to iterate and test multiple versions |

Limited—modifying tooling is expensive and time-consuming |

|

Material & Finish Quality |

Varies by method; suitable for testing and presentation |

Typically more polished; closer to production finish |

|

Best Use Case |

MVPs, concept testing, user feedback, agile development |

Final validation, high-volume production |

Rapid prototyping is faster, more affordable, and far more flexible than traditional prototyping, making it ideal for early testing, iterative design, and low-volume production.

Why This Matters

Rapid prototyping empowers teams to test ideas early and often—without the cost or delay of traditional manufacturing processes. It’s ideal for agile product development, where continuous feedback and iteration are essential to getting the design right before scaling to full production.

Use Cases:

- Rapid prototyping: Concept testing, early-stage validation, UI/UX mockups, low-run physical parts

- Traditional prototyping: Pre-production verification, regulatory compliance, polished display models

Who Is Involved? Roles & Stakeholders

- Industrial and UX Designers: Create and validate early concepts through models or digital interfaces.

- Mechanical Engineers: Ensure structural and functional feasibility of designs.

- Quality Assurance Teams: Test fit, safety, and compliance with regulations.

- Manufacturing Specialists: Advise on method viability and production transfer.

- Stakeholders and End Users: Offer early-stage feedback that can reshape product direction.

Involving all stakeholders from the start ensures alignment and speeds up decision-making.

Benefits of Rapid Prototyping: Business & Development Advantages

Long product cycles and costly trial-and-error processes are no longer sustainable. Rapid prototyping transforms product development by enabling faster iterations, early testing, and smarter decision-making—helping businesses innovate quickly, reduce risk, and align designs with real user needs.

The key advantages of rapid prototyping include faster product development, lower iteration costs, better stakeholder communication, improved design validation, and greater customization—making it an essential strategy for agile innovation.

1. Speed to Market & Iteration

Rapid prototyping drastically accelerates the development timeline—from months to weeks, or even days.

How it helps:

- Test multiple design variations in parallel

- Reduce the delay between design and feedback

- Adapt swiftly to market changes or user insights

Example Tip: Start with low-fidelity mockups to explore concepts, then advance to high-fidelity models for functionality testing.

2. Cost Efficiency & Risk Mitigation

By catching design flaws early, businesses avoid the high costs of post-production changes or tooling rework.

Benefits:

- Eliminate expensive one-off tooling

- Use lower-cost materials in early iterations

- Identify usability or performance issues early

Action Step: Use temporary molds or 3D printing for early-stage testing instead of committing to full-scale manufacturing.

3. Better Communication & Stakeholder Alignment

Visual, interactive prototypes bridge the gap between designers, engineers, executives, and end users.

Use Case: Present realistic prototypes in stakeholder meetings to secure faster buy-in and reduce misalignment.

Tools: Use digital twins, VR mockups, or physical models to facilitate cross-functional understanding.

4. Customization & Agile Design

Rapid prototyping supports agile development and personalized product variations without major production delays.

Key Advantage: Modify digital designs and reprint components in hours—ideal for user-specific products or frequent updates.

Example: Wearables, consumer electronics, and medical devices often rely on rapid iteration for ergonomic and aesthetic refinement.

5. Quality, Testing & Validation

Prototypes aren’t just visual—they’re functional. Teams can test for fit, form, function, and compliance early in the cycle.

Testing Tools:

- Simulations for stress and usability

- User feedback forms and test scripts

- Regulatory compliance mockups (e.g., FDA standards)

Result: Fewer surprises during manufacturing and improved end-user satisfaction.

6. Sustainability & Digital Efficiency

Digital workflows and additive manufacturing minimize waste, reduce material overuse, and support distributed teams.

Sustainability Gains:

- Produce only what you need, when you need it

- Cut energy and shipping costs through local fabrication

- Use digital twins for remote collaboration and validation

Pro Tip: Track energy and material savings per prototype iteration to optimize ROI and reduce your carbon footprint.

|

Advantage |

Business Benefit |

|

Speed to Market |

Faster launches, more iterations |

|

Cost Efficiency |

Lower tooling and testing expenses |

|

Improved Communication |

Better stakeholder alignment and fewer misinterpretations |

|

Customization & Agility |

Personalized product development without delays |

|

Early Testing & Validation |

Reduced failure risk, better compliance |

|

Sustainability & Digital Flow |

Minimized waste, cloud-enabled collaboration |

Why Product Managers Must Understand Rapid Prototyping

Rapid prototyping isn’t just a tool for engineers or designers—it’s a strategic advantage for product managers. Understanding the process empowers PMs to reduce risk, validate ideas early, and align development efforts with real user needs before significant resources are spent.

Key Insight: Rapid prototyping helps product managers test assumptions fast, prioritize with clarity, and make data-driven decisions—ensuring that the product built is the product users actually want.

Turn Assumptions Into Evidence

Rather than relying solely on user interviews or theoretical frameworks, rapid prototyping allows PMs to gather real-world feedback from real users—fast. Clickable mockups, interactive UIs, or functional hardware give teams a glimpse into what works and what doesn’t, well before full-scale development.

Outcome:

✅ Test hypotheses with real users

✅ Uncover usability issues early

✅ Pivot confidently (if needed)

Drive Agile, Iterative Decision-Making

Rapid prototyping works in fast loops. Product managers must guide the process by:

- Setting testing goals

- Prioritizing key features

- Interpreting test results

- Collaborating with design/dev teams

When decisions stall, developers wait. PMs who understand the prototyping process can keep iterations flowing and product momentum high.

Cut Scope Creep, Focus on What Matters

Prototypes naturally trim the fat. If users don’t miss a feature during testing, maybe it doesn’t need to be built at all. This pruning effect helps product managers prioritize functionality that actually moves the needle.

Ask Yourself:

❓ Did users ask for it?

❓ Did they notice it was missing?

❓ Will it improve the core user experience?

Align Cross-Functional Teams

Product managers act as the bridge between vision and execution. By understanding rapid prototyping, PMs can:

- Align stakeholders early using tangible models

- Communicate product direction more clearly

- Reduce misunderstandings between design, engineering, and business teams

|

Benefit |

Why It Matters for PMs |

|

Faster user feedback |

Validate before building |

|

Early risk mitigation |

Spot flaws early, avoid costly rework |

|

Lean prioritization |

Focus only on what adds real user value |

|

Better cross-team alignment |

Keep teams synced with visual clarity |

|

Accelerated time-to-market |

Ship smarter and faster |

How Does Rapid Prototyping Work?

Rapid prototyping (RP) involves several manufacturing technologies, with most relying on layer-by-layer additive manufacturing. However, other methods such as milling, casting, molding, and extrusion are also widely used to create prototypes. This combination of techniques makes rapid prototype development a flexible and efficient approach for transforming digital designs into tangible models.

Key Rapid Prototyping Techniques:

-

Additive Manufacturing (3D Printing)

Builds prototypes layer by layer from digital CAD data. Ideal for complex shapes and reduced material waste. -

Milling & Subtractive Processes

Shapes a block of material into the desired form using milling, grinding, CNC machining, or turning. -

Chipless Shaping

Creates prototypes by forming molds from liquid or semi-liquid materials (e.g., casting, pressure sintering, or molding). -

CNC Machining Prototypes

Offers high precision and strength, making it suitable for functional testing and end-use components.

Types of Rapid Prototyping: Technologies and Methods Explained

Rapid prototyping comprises methods like 3D printing, CNC machining, silicone casting, AI-driven automation, and virtual modeling. Each technique serves different prototype needs—whether for fast iteration, high precision, scalability, or immersive validation—so teams can align their approach to speed, cost, and product requirements effectively.

To bring product ideas to life quickly and cost-effectively, teams use a variety of rapid prototyping technologies—each tailored to different stages of development, materials, and performance goals. From additive methods like 3D printing to precision CNC machining, silicone casting, and emerging AI/XR-powered approaches, choosing the right method helps teams innovate smarter and faster.

1. Additive Manufacturing (e.g., FDM, SLA, SLS)

- What it is: Builds prototypes layer by layer directly from digital models.

- Technologies:

- Fused Deposition Modeling (FDM) – Uses thermoplastics like ABS or PLA; cost-effective, great for simple parts.

- Stereolithography (SLA) – Offers high detail and smooth surface finish via UV-resin curing.

- Selective Laser Sintering (SLS) – Fuses powdered materials for durable, functional parts.

- Best for: Functional components, form validation, fit testing.

- Why use it: Fast, low material waste, flexible for small batches.

2. Subtractive Methods (e.g., CNC Machining)

- What it is: Starts with a solid material block and removes material to achieve final shape.

- Advantages: Exceptional dimensional accuracy, smooth finishes, and compatibility with metals and engineering plastics.

- Best for: Prototypes that mimic final production parts—ideal for structural, mechanical, or load-bearing applications.

3. Molding & Silicone Casting

- What it is: Creates multiple copies using silicone or soft tooling molds.

- Examples: Vacuum casting, urethane molding.

- Best for: Small-batch production with consistent quality.

- Benefits: Cost-efficient after initial mold setup, visually realistic outputs.

4. Cutting-Edge Techniques (HARP, CLIP)

- HARP (High-Area Rapid Printing): Capable of printing large, accurate parts in minutes.

- CLIP (Continuous Liquid Interface Production): Delivers smooth surfaces and rapid curing paths.

- Use Cases: Critical for high-speed, high-surface-quality requirements—e.g., aerospace models, medical devices.

5. Automation, AI & Smart Prototyping

- What it is: Leverages AI-driven CAD adjustments, predictive testing, and robotic validations.

- Advantages: Reduces human error, accelerates iteration, scales workflows.

- Ideal for: Enterprises needing high efficiency and repeatability.

6. Digital & Virtual Prototyping

- What it is: Uses simulation and virtual models instead of physical parts.

- Advantages: No material waste, instant revisions, enables remote collaboration.

- Best for: UI/UX design, layout exploration, systems testing, and early error-checking.

7. XR & AI-Powered Prototyping

- What it is: Immersive VR or AR environments combined with AI interface mockups and “vibe coding”.

- Advantages: Cuts physical prototyping costs, fosters stakeholder alignment, improves empathy in design.

- Perfect for: Visual walkthroughs, interface testing, and collaborative early-stage feedback.

|

Method |

Strengths |

Ideal Use Cases |

|

Additive (FDM/SLA/SLS) |

Fast, flexible, minimal waste |

Early prototypes, concept testing, visual validation |

|

Subtractive (CNC Machining) |

High precision, durable materials |

Engineering validation, structural parts |

|

Molding & Casting |

Reproducible, cost-effective for small batches |

Low-volume production, functional prototypes |

|

HARP / CLIP |

Ultra-fast, high-detail prints |

Aerospace, medical, high-end visual prototypes |

|

AI / Automated Prototyping |

Consistent, quick decisions, scalable |

Large-volume or enterprise-scale R&D |

|

Digital / Virtual Prototyping |

Waste-free, rapid iteration, remote collaboration |

UI/UX, architectural fit, early-stage validation |

|

XR / VR Prototyping |

Immersive, collaborative, empathic |

Interface design, stakeholder demos |

Why This Matters

This structured breakdown helps product teams choose the most suitable rapid prototyping method at every stage—from early ideation and form testing to functional validation and final design.

Rapid Prototyping Tools

Tools are the software and hardware platforms that power rapid prototype development.

Software Tools

-

Fusion 360, SolidWorks – CAD and 3D design.

-

Axure ($25–49/month) – Complex, large-scale projects with conditional logic.

-

Justinmind (Free – $39/month) – Mobile & web prototyping with responsive design.

-

Proto.io ($29–199/month) – High-fidelity prototypes with animations.

-

UXPin ($15–39/month) – Real-time collaboration with developers.

-

HotGloo ($13–54/month) – Simple UI for early-stage wireframes.

Hardware Tools

-

3D Printers (FDM, SLA, SLS) – Physical prototype production.

-

CNC Machines – High-precision subtractive prototyping.

-

Laser Cutters – Flat part production for quick iterations.

-

Casting Equipment – Small-batch silicone or urethane molding.

| Tool | Pricing (per user/month) | Platform Type | Best For | Standout Features |

|---|---|---|---|---|

| Axure | Pro: $25–29 Team: $42–49 |

Standalone (desktop) | Complex, large-scale projects | Conditional logic, advanced interactivity, strong documentation & specification export |

| Justinmind | Free plan Standard: $9 Pro: $19 Enterprise: $39 |

Standalone (desktop) | Beginners to enterprises | Mobile & web prototyping, responsive design, detailed specs, reusable components |

| Proto.io | Freelancer: $29 Startup: $49 Agency: $99 Corporate: $199 |

Web-based | High-fidelity, animation-rich prototypes | Strong animation support, Photoshop/Sketch import, native device preview apps |

| UXPin | Basic: $15 Advanced: $29 Merge AI: $39 |

Web-based | Design teams & developers | Real-time collaboration, large widget library, imports from Sketch/Photoshop, component-driven design |

| HotGloo | Group: $13 Team: $27 Agency: $54 |

Web-based | Low-fidelity, fast wireframes | Browser-based, simple UI, team collaboration, ideal for early-stage wireframes |

Applications & Industry Use Cases

Rapid prototyping supports industries such as automotive, aerospace, healthcare, consumer goods, fashion, and food to accelerate concept validation, reduce development costs, and customize products using techniques like 3D printing, CNC machining, and AI-powered fabrication.

Industries from automotive to healthcare, consumer goods to fashion, and even food production are harnessing rapid prototyping to innovate smarter, faster, and more cost-effectively. By turning ideas into tangible forms quickly, these sectors are validating concepts, reducing risk, and personalizing products like never before.

1. Automotive & Aerospace

Rapid prototyping accelerates design validation in vehicle and aircraft production by testing aerodynamics, structural fit, and component integration before moving to full-scale manufacturing.

Key Benefits:

- Weight reduction through iterative lightweighting

- Faster design-to-test cycles

Example: Companies like Tesla and Rivian leverage 3D printing for interior components and functional mounts, significantly speeding up development.

2. Healthcare & Medical Devices

Custom implants, surgical tools, and prosthetic devices benefit immensely from personalized, precision-first designs. Rapid prototyping also supports regulatory compliance with ISO and FDA standards.

Use Cases:

- Patient-specific implants

- Surgical guides tailored to anatomy

- Biocompatibility testing for FDA approval

3. Consumer & Industrial Products

From ergonomic tools to refined consumer electronics, rapid prototyping enables real-world testing and rapid feedback integration during product design.

Impact:

- Enhanced usability via early-stage user testing

- Real-world feedback informs faster design revisions

4. Food, Fashion & Wearables

Innovations like 3D-printed chocolates, custom shoes, or smart wearables are made possible with rapid prototyping. AI-driven platforms like ProtoBot allow teams to embed tech and personalization into wearable designs quickly.

Advantages:

- Customization at scale

- Fast iterations on textures, sizing, and embedded features

5. Cloud-Based & Distributed Fabrication

Remote collaboration and on-demand production are powered by cloud platforms, enabling seamless workflows from design to fabrication—wherever teams are located.

Tools & Services:

- Autodesk Fusion 360

- Xometry

- StartUs Insights

Benefits:

- Access to global manufacturing at your fingertips

- Scale rapidly without infrastructure investment

|

Industry |

Key Uses |

Rapid Prototyping Benefits |

|

Automotive & Aerospace |

Component fit, aerodynamic testing |

Speed, weight optimization, functional testing |

|

Healthcare |

Medical implants, surgical instruments, prosthetics |

Customization, precision, regulatory alignment |

|

Consumer Products |

Ergonomic testing, usability validation |

Quicker feedback, improved UX |

|

Food, Fashion & Wearables |

Custom design and tech integration |

Personalization, fast format refinement |

|

Cloud-Based Fabrication |

Remote design-to-production workflows |

Global access, cost-effective scaling |

Rapid Prototyping Process Breakdown

Successful rapid prototyping goes beyond just speed—it demands a strategic workflow that always aligns prototype fidelity with your product objectives. Whether you’re creating a physical component or a digital interface, each stage of the process—from purpose setting to validation—must be deliberate and goal-oriented. This breakdown helps teams move efficiently from concept to production-ready design with clarity and purpose.

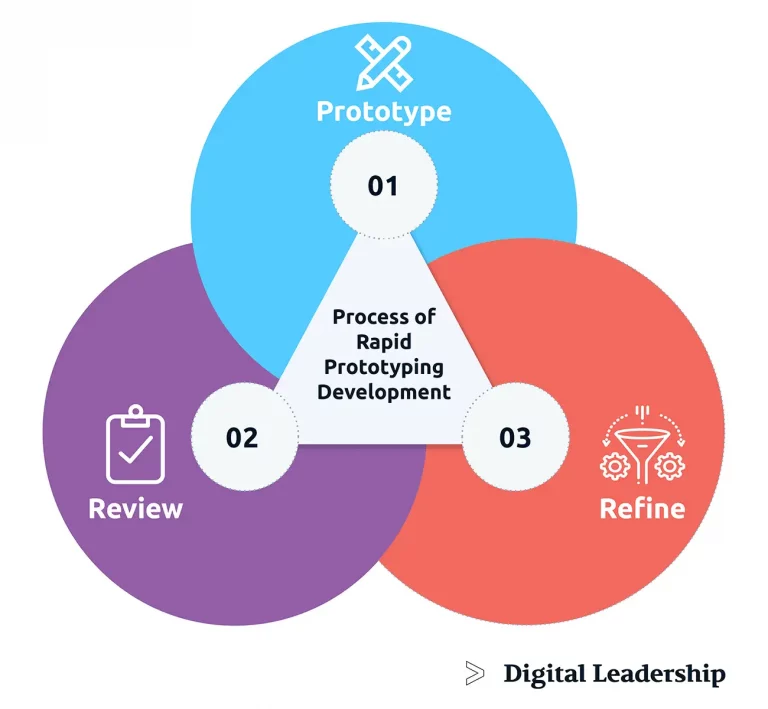

Rapid prototyping succeeds through a structured workflow: define testing objectives and fidelity, model and simulate digitally, build physical versions, gather feedback, iterate, and then finalize for production—ensuring insights at each stage.

1. Define Objectives & Fidelity Requirements

- Clarify Your Goals: What aspect needs testing—form, function, or user feel?

- Match Fidelity to Goal:

- Low-fidelity prototypes for early exploration and quick feedback

- High-fidelity prototypes for realistic testing, stakeholder buy-in, or user evaluation

Why It Matters: Clear definitions help avoid wasted effort and focus testing where it matters most.

2. Digital Modeling & Simulation

Leverage CAD and simulation tools to validate designs visually and technically:

- Test structural integrity

- Evaluate usability thresholds

- Simulate user workflows

Digital modeling allows rapid revisions—ideal for catching flaws early, without physical waste.

3. Physical Prototyping & Refinement

Choose the appropriate method—3D printing, CNC machining, or molding—based on your fidelity needs, material, and function.

- Iterate fast: Build, test, refine in cycles

- Stay agile: Physical models provide tangible insight to improve design coherence

4. Testing, Feedback & Iteration

Use structured feedback tools such as Qualaroo or UserTesting to collect and act on input efficiently.

Prototype Feedback Checklist:

- What is the prototype’s main goal?

- What features work well?

- What needs improvement?

- Would users prefer this over existing alternatives?

This use-case-oriented feedback loop ensures focused improvements and better iteration quality.

5. Final Validation & Transition to Manufacturing

Before scaling:

- Confirm material specifications and production tolerances

- Ensure compatibility with tooling or low-volume manufacturing methods

Preparing for production means aligning prototype lessons with manufacturing realities—ensuring your design is both functional and manufacturable.

Why This Process Works

This structured framework balances the need for speed with strategic insight. It helps teams:

- Accelerate iteration without sacrificing quality

- Reduce risks through early testing

- Align prototypes with market needs and production constraints

Process Overview Table

|

Process Stage |

Key Activities |

Outcome |

|

Define Objectives & Fidelity |

Clarify prototyping goals and fidelity level |

Focused and resource-efficient testing |

|

Digital Modeling & Simulation |

CAD and simulated testing |

Early insight without physical waste |

|

Physical Prototyping & Refinement |

Build, test, and refine prototypes |

Real-world understanding of form and function |

|

Testing, Feedback & Iteration |

Use structured feedback tools and iteration plans |

Targeted improvements and validation |

|

Validation & Manufacturing Transition |

Confirm materials, tooling, and scalability |

Production-ready, low-risk design |

Cost Reduction & Efficiency Optimization

1- Material Selection & Waste Reduction

Choosing the right materials can significantly lower costs and improve sustainability. Lightweight, recyclable, or biodegradable options like PLA or ABS in 3D printing can reduce both price and environmental impact.

Tips:

- Use low-cost materials for early iterations.

- Reserve high-performance materials for final validation.

- Optimize part geometry to reduce material usage.

2- Digital vs. Physical Trade-Offs

When to use digital prototypes:

- For early-stage testing

- When collaborating remotely

- To minimize waste

When physical prototypes are better:

- For testing ergonomics, usability, or durability

- When regulatory compliance is needed

- When stakeholder buy-in requires tangible demos

|

Criteria |

Digital Prototyping |

Physical Prototyping |

|

Cost |

Lower |

Higher |

|

Feedback Speed |

Instant |

Slower |

|

Realism |

Limited |

High |

|

Sustainability |

High |

Moderate |

3- Agile Tooling to Speed Delivery

Agile tooling uses modular, flexible tooling solutions to reduce time and cost in transitioning from prototype to production.

Benefits:

- Quicker setup

- Customization-friendly

- Suitable for pilot runs

4- Automation & Cloud-Enabled Workflows

Integrating cloud platforms and AI tools into prototyping workflows accelerates collaboration and consistency.

Tools to Explore:

- Autodesk Fusion 360 for cloud-based design

- AI platforms for automated quality inspection

- Digital twin simulations for remote validation

Case Studies & Real-World Examples

Rapid prototyping isn’t just a buzzword—it’s a proven game-changer across industries. From electric vehicle manufacturers slashing design cycles to wearable tech brands enhancing comfort through user feedback, the real-world impact is clear. These case studies highlight how leading companies are using rapid prototyping not only to accelerate innovation but also to drive sustainability, improve user experience, and stay ahead of the curve in fast-moving markets.

5- Automotive Innovations (Rivian)

Rivian’s in-house prototyping lab uses 3D printing and CNC machining to develop vehicle components rapidly—cutting design-to-test cycles from weeks to days.

Industrial & Consumer Products (Photocentric, boAt Lifestyle)

Photocentric uses photopolymer printing to accelerate time-to-market for electronics. boAt Lifestyle applied agile prototyping for ergonomic testing in wearables, increasing user satisfaction.

XR or AI-Driven UI Prototyping

Companies like ProtoBot and Figma use AI to prototype digital interfaces instantly—allowing real-time collaboration and instant UI feedback without code.

Sustainability Success Stories

Startups like Notpla use sustainable materials (e.g., seaweed) and rapid prototyping to iterate eco-friendly packaging, reducing plastic use by 80%.

Rapid Prototyping Services vs. In-House: What’s Right for You?

Choosing between outsourced rapid prototyping services and building an in-house setup depends on your product development needs, volume, and speed requirements. Each approach has distinct advantages and trade-offs—understanding these will help you optimize cost, time-to-market, and production flexibility.

Outsourced rapid prototyping is ideal for occasional use, large or complex parts, and specialty materials. In-house prototyping offers lower long-term costs, faster iterations, and greater control over design cycles.

Outsourced Rapid Prototyping Services

Best for:

- Low-volume or one-off parts

- Large components

- Exotic or industrial-grade materials

- Teams without internal fabrication capabilities

Popular Services:

- Protolabs

- Xometry

- Hubs

- Fictiv

- Local service bureaus

Advantages:

✅ Access to a wide range of technologies (SLA, SLS, CNC, MJF, injection molding)

✅ Expert material consultation

✅ Professional-grade surface finishing

✅ No upfront equipment investment

Limitations:

❌ Longer lead times (often days to weeks)

❌ Higher per-part cost, especially at scale

❌ Limited iteration agility

In-House Rapid Prototyping

Best for:

- High iteration cycles

- Daily or weekly prototype needs

- Teams prioritizing speed and ownership

- Businesses scaling agile hardware workflows

Benefits of In-House Setup:

✅ Instant turnaround (same-day prototyping)

✅ Lower cost-per-iteration

✅ Greater confidentiality and IP control

✅ Scalable capacity with multiple printers

✅ Ability to prototype in parallel using different materials

Considerations:

- Requires initial investment in hardware and training

- Limited by in-house equipment’s size and material range

- May still need to supplement with external services for specialty parts

|

Criteria |

Outsourced Services |

In-House Prototyping |

|

Speed |

Days to weeks |

Hours to days |

|

Cost per Part |

Higher (especially with multiple rounds) |

Lower with high volume or frequent use |

|

Initial Investment |

None |

Moderate (3D printers, training) |

|

Material/Tech Access |

Extensive |

Depends on equipment |

|

Iteration Flexibility |

Limited |

High (multiple daily iterations possible) |

|

Scalability |

Limited |

Easily scalable with added printers |

|

Expert Support |

Included |

May require internal upskilling |

Pro Tip: Use a Hybrid Model

Many teams benefit from a hybrid approach—using in-house prototyping for everyday development, and outsourcing for large, specialized, or high-fidelity prototypes. This balances cost, flexibility, and access to advanced capabilities.

Rapid Prototyping – Frequently Asked Questions

1- What Is the Difference Between Rapid and Traditional Prototyping?

Rapid prototyping emphasizes speed, low-cost iterations, and flexibility using digital or additive technologies. Traditional methods focus on polish and are often costlier and slower.

2- How Can Rapid Prototyping Improve My Product Development Process?

It enables faster testing, earlier feedback, and better alignment with customer needs—cutting risk and reducing time to market.

3- What Are the Main Types of Rapid Prototyping?

- Additive (FDM, SLA, SLS)

- Subtractive (CNC machining)

- Molding (silicone, urethane)

- Digital (simulations, virtual models)

4- Can Rapid Prototyping Scale to Industrial Applications?

Yes. Industries like aerospace, automotive, and medical devices use rapid prototyping at every stage—from R&D to market launch.

5- How Do I Choose the Right Material?

Match material properties to your use case:

- PLA for concept models

- Nylon or ABS for functional testing

- Medical-grade resin for healthcare applications

6- Does Rapid Prototyping Help Reduce Development Costs?

Absolutely. By catching errors early and avoiding tooling for early iterations, you save on rework, material, and engineering time.

7- How Does Digital Prototyping Enhance the Process?

Digital workflows reduce waste, increase iteration speed, and improve collaboration—especially for remote or distributed teams.

Conclusion

Rapid prototyping is more than a development shortcut—it’s a strategic safeguard for product managers. By testing ideas early with real users, PMs gain reliable validation or actionable feedback that guides necessary pivots. This reduces the risk of launching products that miss the mark.

Equally important, prototyping makes abstract ideas tangible. Interactive models bridge communication gaps between product, design, and development teams—ensuring alignment from concept to execution. This clarity prevents costly misunderstandings and accelerates the product lifecycle.

When it comes to prototyping tools, there’s no “one-size-fits-all.” Each has strengths suited to specific needs:

-

Axure & Justinmind – Advanced tools for complex interactivity.

-

Justinmind: Better for handling data, libraries, and team collaboration.

-

Axure: Stronger in complex interactions, backed by a large learning community.

-

-

Proto.io – Ideal for mobile prototypes rich in animations.

-

UXPin – Great for collaboration and managing entire design projects.

-

HotGloo – Beginner-friendly, perfect for quick, low-fidelity prototypes.

👉 The key is to evaluate your project requirements and experiment with free trial versions before committing. The right tool is the one that fits your workflow, team, and goals—not necessarily the most powerful one.

Ultimately, rapid prototyping enables product managers to deliver better products, faster—with fewer surprises, stronger user trust, and higher confidence at launch.

Related Posts

Design Thinking: Guide to Process, Methods & Frameworks

People with their values and needs serve as a source of inspiration1

View Full articleImportant But Underserved Customer Needs: How to Identify?

Creating products and services that yield more profits largely depends on understanding1

View Full articlePains and Gains: Understanding Your Customer Needs

The value proposition of any successful business is deeply tied to the1

View Full articleOutcome-Driven Innovation (ODI) For Putting JTBD Theory into Action

Outcome-driven innovation (ODI) is a strategic approach that operationalizes the Jobs-to-be-Done (JTBD)1

View Full article

Book How to Create Innovation

Book How to Create Innovation